View Large

View Large

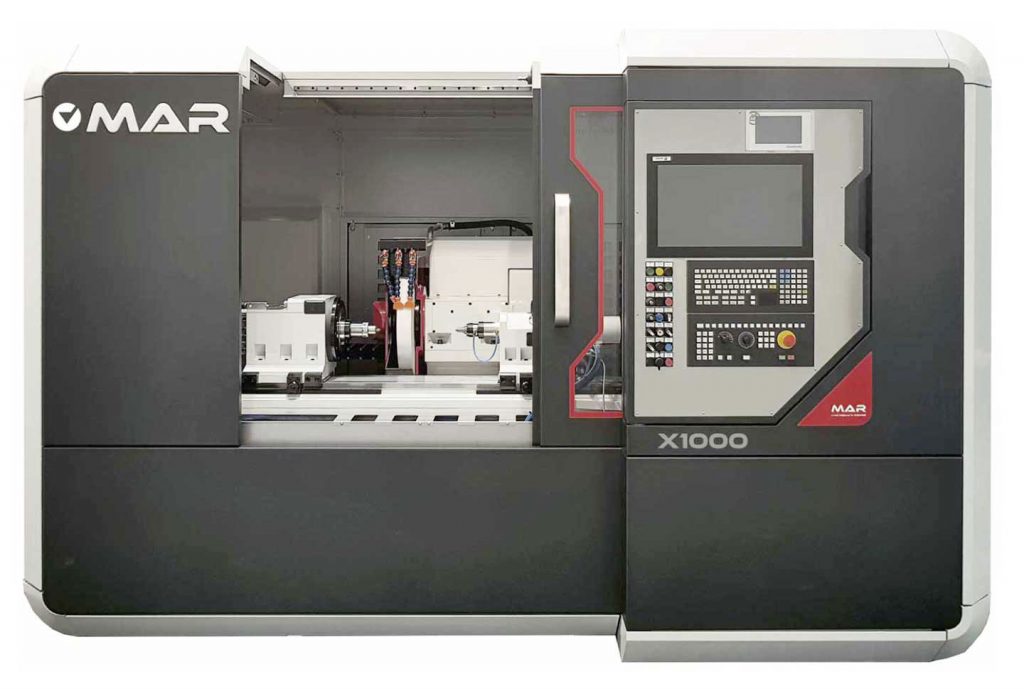

MAR X500

The little one for great duty

X500 is one of the round grinding machines for external or internal diameters with mobile uprights. It belongs to the X family, and it is defined as the small one for great duty. In fact, despite its small size it is able to work pieces of maximum length 500 mm and with a rotating diameter of 250 mm or 360 mm.

X500 is a high-performance grinding machine

This machine is born of special care for design, construction, and use of the highest quality raw materials and technologies.

X500 components

The natural granite base, for example, has three levelling points to guarantee stability and perfect support on every surface. The processing of this component is carried out with great accuracy and precision to ensure reliability and durability.

A new features X500 compared to other grinding machines is the connection from the multi-spindle turret Torque through the base to get directly into the electrical cabinet, reducing cable lengths and eliminating joints and extensions. The turret is designed to accommodate up to two electrospindles with variable configurations.

The workpiece head is universal and designed for machining between fixed and rotating centres thanks to the Torque motor and the Morse 4/ ASA 4 connection cone (optional Morse 5/ ASA5). Alternatively, the work head with electrospindle for cantilevered machining with speeds up to 2000 rpm and housing for diamond disc is available. The group can be moved automatically by a ball screw coupled to a digital brushless motor, according the arrangement on linear guides and the electro-pneumatic brake locking. The position is controlled by an absolute optical line pressurized.

Other X500 grinding machine features are:

- THE TAILSTOCK with manual lever movement and thrust with adjustable preload spring with Morse 3 or Morse 4 connection;

- the dinghy sliding on adjustable bronzines, which can feature the pneumatic movement of opening and closing to facilitate the insertion of the pieces;

- the fine adjustment of the cylindrical shape, equipped in a standard way in the tailstock, can feature an engine (managed by the NC), to reduce the time;

- Process programming is optimized by direct insertion of the correction value into a CNC mask.

All X500’s high-performance components and features are cross-laid with X and Z axes which, together with the movement of the state-of-the-art linear motors controlled by absolute optical pressure lines, allow a limited footprint of 2200 mm x 2200 mm, thus occupying less than 5 square meters.

Hardware and software of X500 grinding machine

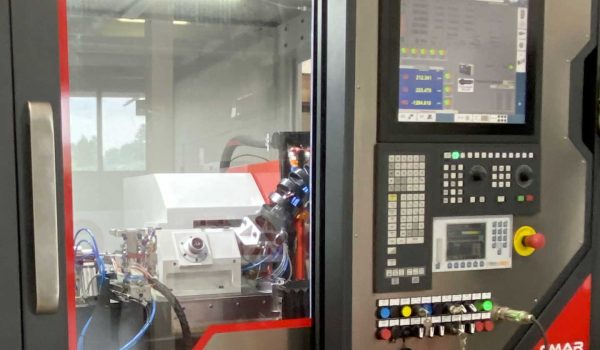

Like the other machines in the MAR grinding machine family, TITAN is featured with the CN package hardware with the option of choosing between Fagor or Siemens systems, which include drives, motors, and peripherals machine management. The MAR digital technology also includes remote diagnosis tools to be always at the customer’s side in every moment.

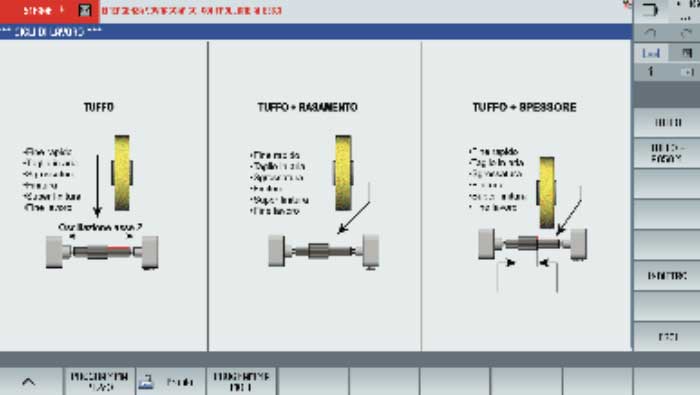

MAR has also fully developed the machine control software, intuitive and straightforward, with a touch screen interface that offers complete control of the machine to operate cycles in total autonomy.

Customization and support

MAR offers the best possible service by collaborating with important companies in the sector to provide all the required customizations to its customers to carry out specific performing work cycles and create a high-quality final product thanks to the processes performed outstanding reliability by MAR grinding machines.

MAR, even after the construction and commissioning of the machine, remains at your side at all times, offering maintenance and support to avoid downtime expensive and easily avoidable. To facilitate any ordinary and non-routine maintenance process, MAR has created TITAN with a design and a layout of the various components aimed not only at optimal operation but also at simple accessibility and easy maintenance in every part of the machine to minimize the time of intervention of its technician’s specialists, who will always know where to act thanks to the field buses and diagnostic systems on each machine.

Finally, MAR also offers a programmed maintenance service to maintain the machine’s workings’ highest quality.