View Large

View Large

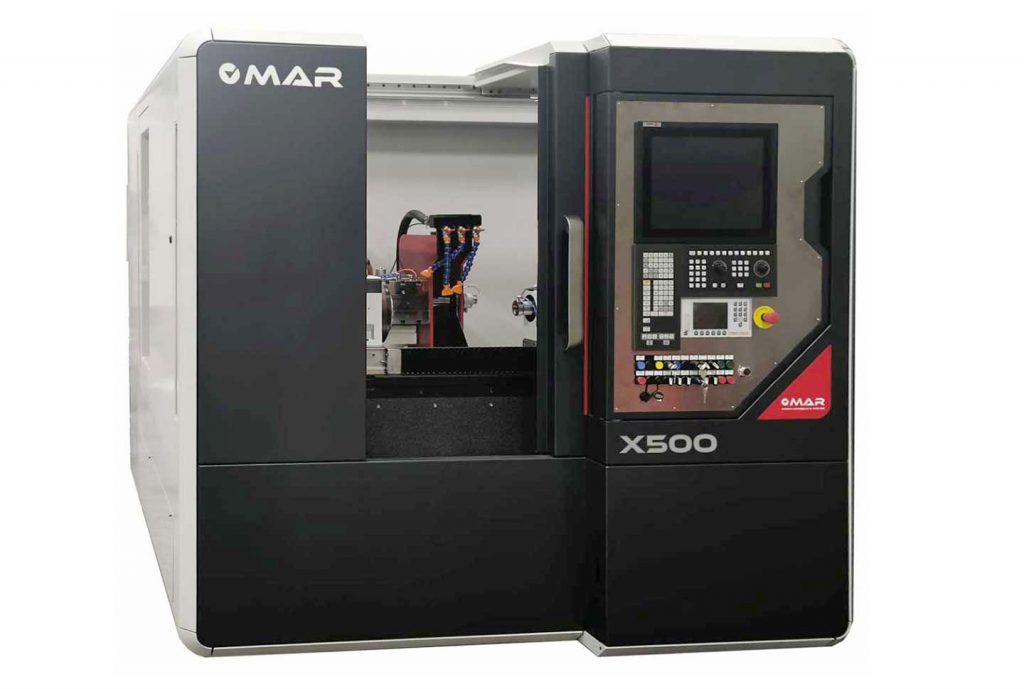

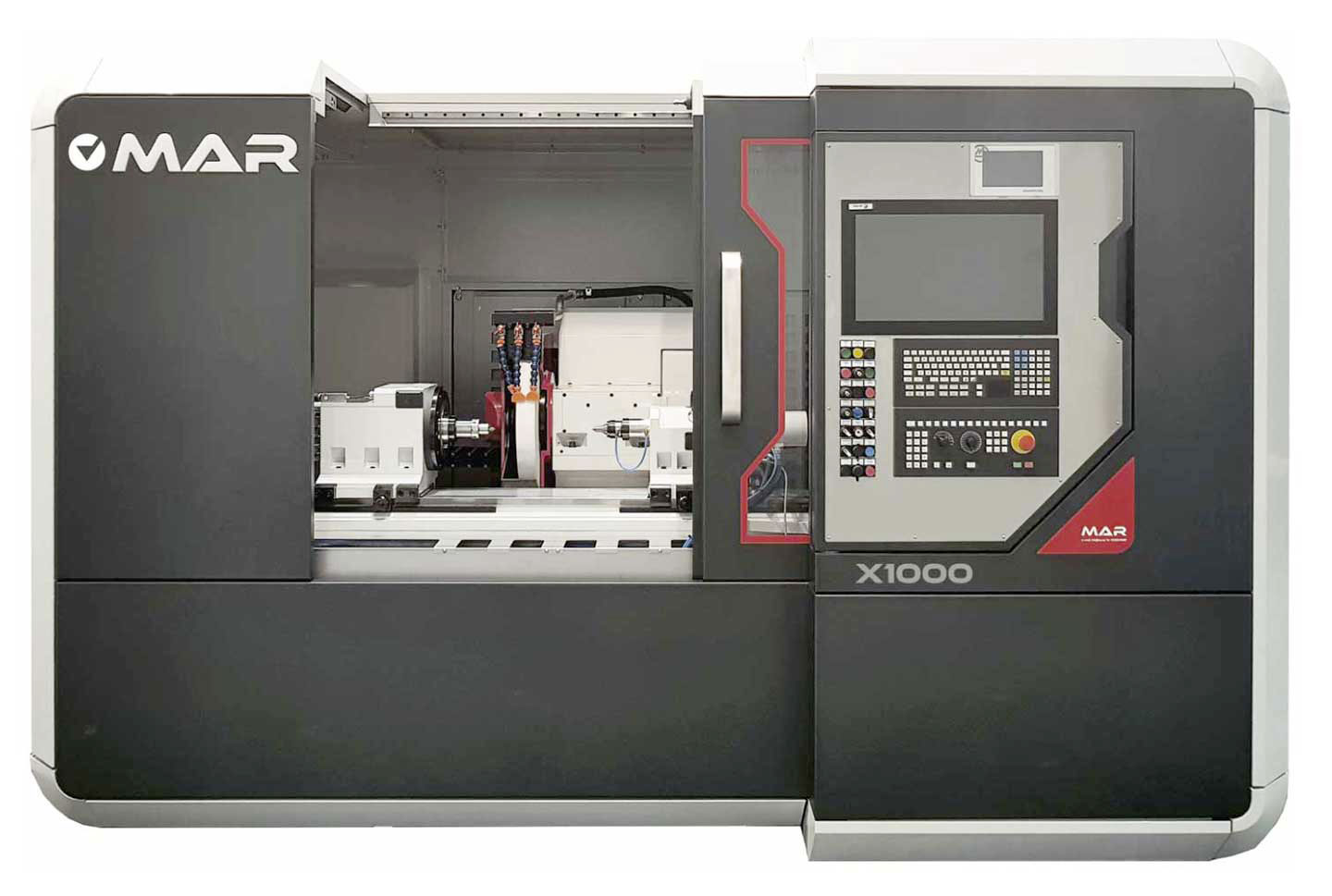

MAR X1000

The Compact with Mobile Upright

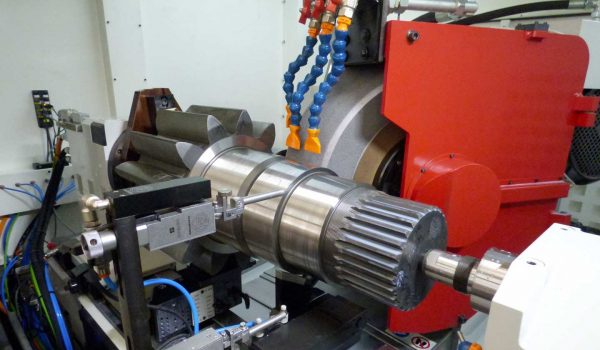

X1000 is one of the MAR Mobile Upright Cylindrical Grinding Machines for operations involving the machining of external and/or internal diameters up to 1000 mm in length and 360 mm or 460 mm in rotating diameter.

X1000 is designed to the slightest detail

We provide a machine tool that makes the most out of a small space to offer high-quality machining.

X1000 components

The machine base is a made in Italy one-block of natural granite. It is produced with the most advanced technologies to ensure stability and an optimal working surface. Thanks to this component, higher speed and high-quality grinding are ensured during machining, also guaranteeing durability.

The project includes a mobile upright to optimize spaces. MAR has managed to contain all the components in a 3200 mm x 2400mm space without sacrificing solidity. To optimize spaces, a dedicated part loading system is available and managed directly from the user interface.

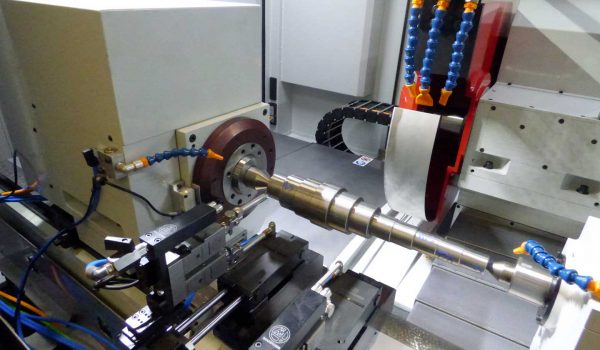

X1000 provides both internal and external diameters machining in its configuration and operation. For example, among the components of the standard configuration for outdoor it uses wheel holder spindle left right or right tiltable with various sizes based on the machining that must be performed:

Electrospindle on bearings 508 mm x 80 mm x 203,2 mm

Electrospindle on bearings 610 mm x 80 mm x 203,2 mm

Spindle on hydraulic bushings 508 mm x 100 mm x 203,2 mm

Spindle on hydrodynamic bushings 610 mm x 100 mm x 203,2 mm

Spindle on hydrodynamic bushings 610 mm x 130 mm x 304.8 mm

Spindle on hydrodynamic bushings 610 mm x 190 mm x 304.8 mm

The peripheral speed management is simply given to the CNC in each version of the grinding machine, as well as the automatic wheel balancing which is integrated in the spindle together with the grinding wheel/piece contact sensor.

X1000 meets the preferences and needs of its users with the possibility of mounting a traditional kinematics with recirculation ball screws or state-of-the-art linear motors. Thanks to its modulability, the X1000 allows you to install your ideal support unit on both the longitudinal and transverse axes.

Another customization, available for your X1000, is the one related to the workhead with belt options or direct drive Torque: the belt version has a universal spindle and has a Morse 5 – ASA 5 cone for the attachment of the grip, instead, the Torque version adds a micrometric angular control for machining complex profiles or profile tracking. In both modes you can choose the tip height of 180 mm or 230 mm. The group moves along the fixed bench by means of a rack.

Finally, the X1000 grinding machine features the all-in-one tailstock system that has either manually controlled lever movement or automatic with pedal, spring thrust or hydraulic piston for heavy weights. The cylindrical parts can be corrected by a practical front knob equipped with an optical scale

Hardware and software of X1000 grinding machine

Like the other machines in the MAR grinding machine family, the X1000 features CN package hardware with the option of choosing between Fagor or Siemens systems, which include drives, motors and management peripherals for the machine. The digital technology MAR also includes remote diagnosis tools to be always at the customer’s side in every moment of need.

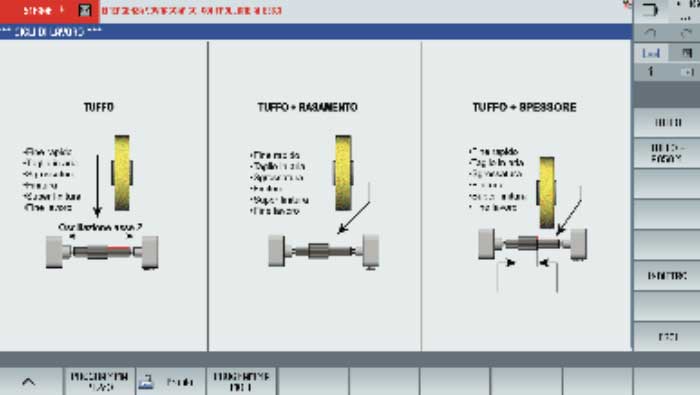

MAR has also fully developed the machine control software, simple and intuitive, with an interface that uses a touch screen that offers complete control of the machine to operate cycles in total autonomy.

Customization and support

MAR offers the best possible service by collaborating with important companies in the sector to provide all the required customizations to its customers to carry out specific performing work cycles and create a high-quality final product thanks to the processes performed outstanding reliability by MAR grinding machines.

MAR, even after the construction and commissioning of the machine, remains at your side at all times, offering maintenance and support to avoid downtime expensive and easily avoidable. To facilitate any ordinary and non-routine maintenance process, MAR has created TITAN with a design and a layout of the various components aimed not only at optimal operation but also at simple accessibility and easy maintenance in every part of the machine to minimize the time of intervention of its technician’s specialists, who will always know where to act thanks to the field buses and diagnostic systems on each machine.

Finally, MAR also offers a programmed maintenance service to maintain the machine’s workings’ highest quality.