View Large

View Large

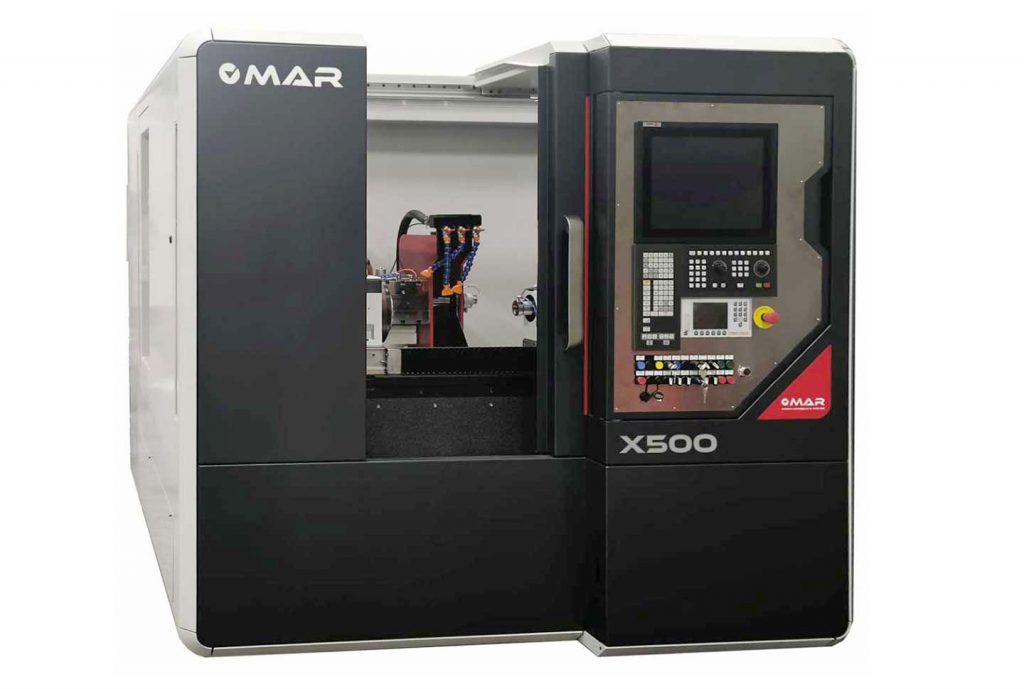

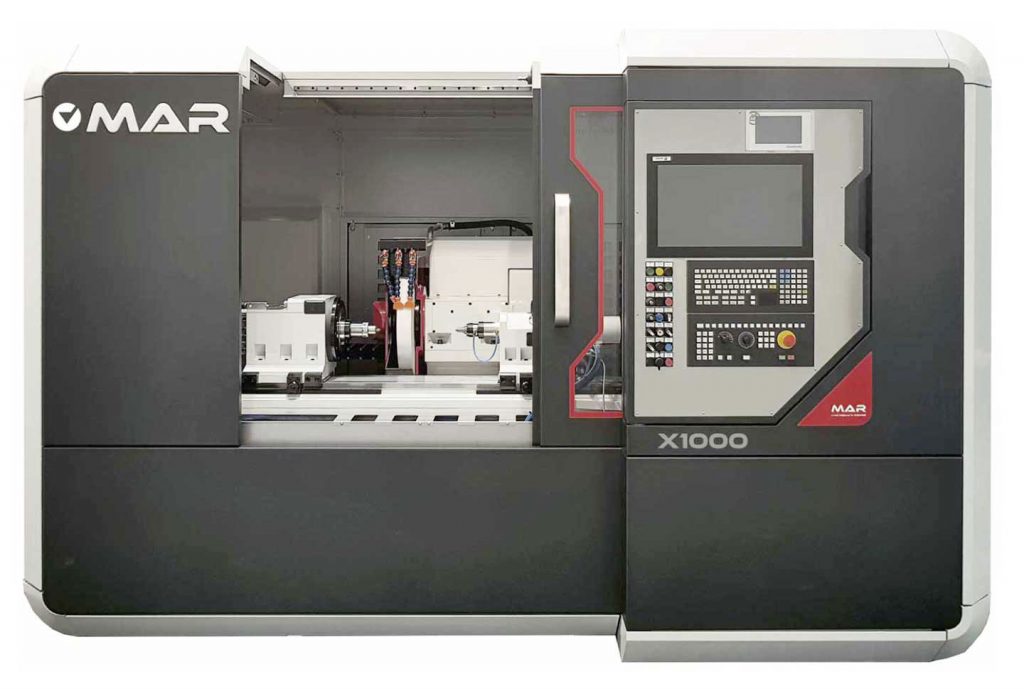

MAR Titan

The "all-around" for any need

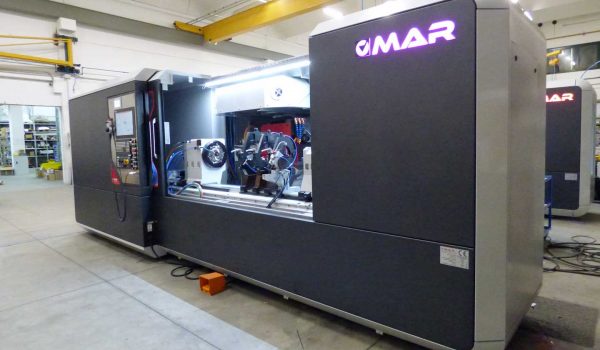

TITAN is the universal grinding machine par excellence, as well as the first machine developed by MAR, who set three different sizes of grinding machines among its product range. TITAN is a grinding machine for external or internal diameters with a mobile panel, modular in size and suitable for operating up to 1,000, 1,500, or 2,000 mm in length and a rotating diameter of 360 or 460 mm.

TITAN is a high-performance grinding machine.

This machine is born of special care for design, construction, and use of the highest quality raw materials and technologies.

TITAN mechanical components

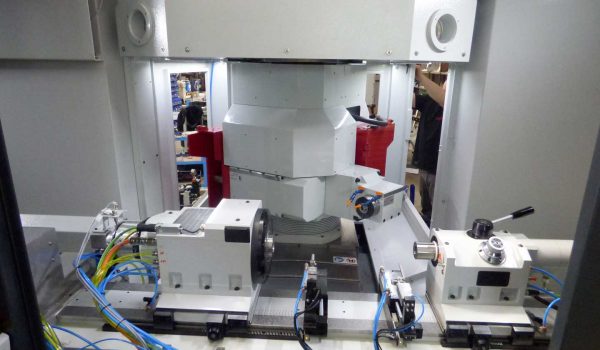

Specifically, TITAN’s base is made of a block of granite, treated in Italy by the best companies in this sector to achieve maximum precision and high durability. The machine is available in three different length sizes to realize projects of all kinds thanks to a modular, precise and efficient grinding.

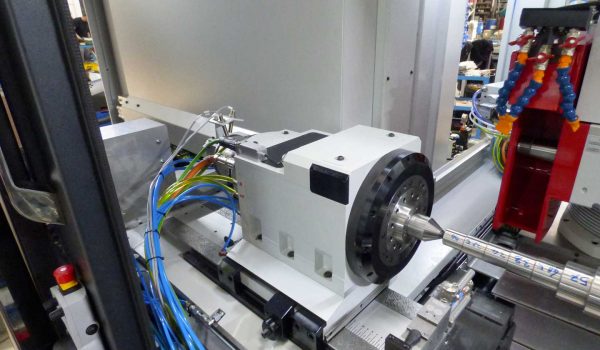

There are two available heights, 180 and 230 mm, which allow the rotation of pieces up to 460 mm and 150 kg cantilevered. The transverse and longitudinal axes can be equipped with a brushless motor screw–coupled to recirculation of spheres or with linear motors controlled by absolute optical line.

TITAN is also equipped with a tailstock unit with manual-controlled movement by a lever or automatically-controlled by a pedal, by spring, or by hydraulic piston.

The cylindrical correction is made by using a front knob equipped with an optical scale and the group’s movement along the bench is through a rack, easy to use for preparation operations.

Hardware and software of TITAN grinding machine

Like the other machines in the MAR grinding machine family, TITAN is featured with the CN package hardware with the option of choosing between Fagor or Siemens systems, which include drives, motors, and peripherals machine management. The MAR digital technology also includes remote diagnosis tools to be always at the customer’s side in every moment.

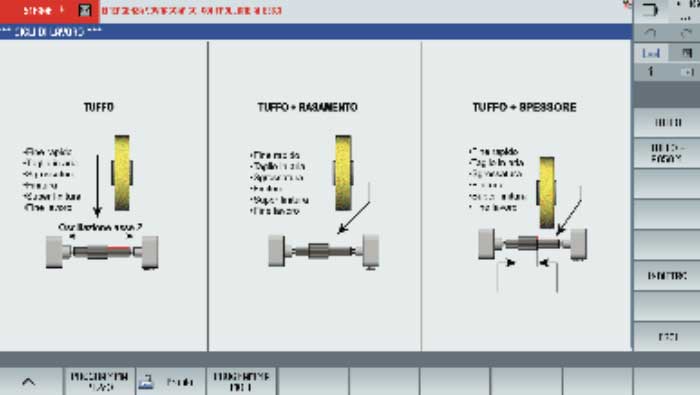

MAR has also fully developed the machine control software, intuitive and straightforward, with a touch screen interface that offers complete control of the machine to operate cycles in total autonomy.

Customization and support

MAR offers the best possible service by collaborating with important companies in the sector to provide all the required customizations to its customers to carry out specific performing work cycles and create a high-quality final product thanks to the processes performed outstanding reliability by MAR grinding machines.

MAR, even after the construction and commissioning of the machine, remains at your side at all times, offering maintenance and support to avoid downtime expensive and easily avoidable. To facilitate any ordinary and non-routine maintenance process, MAR has created TITAN with a design and a layout of the various components aimed not only at optimal operation but also at simple accessibility and easy maintenance in every part of the machine to minimize the time of intervention of its technician’s specialists, who will always know where to act thanks to the field buses and diagnostic systems on each machine.

Finally, MAR also offers a programmed maintenance service to maintain the machine’s workings’ highest quality.