View Large

View Large

MAR MCR

The little inspection center

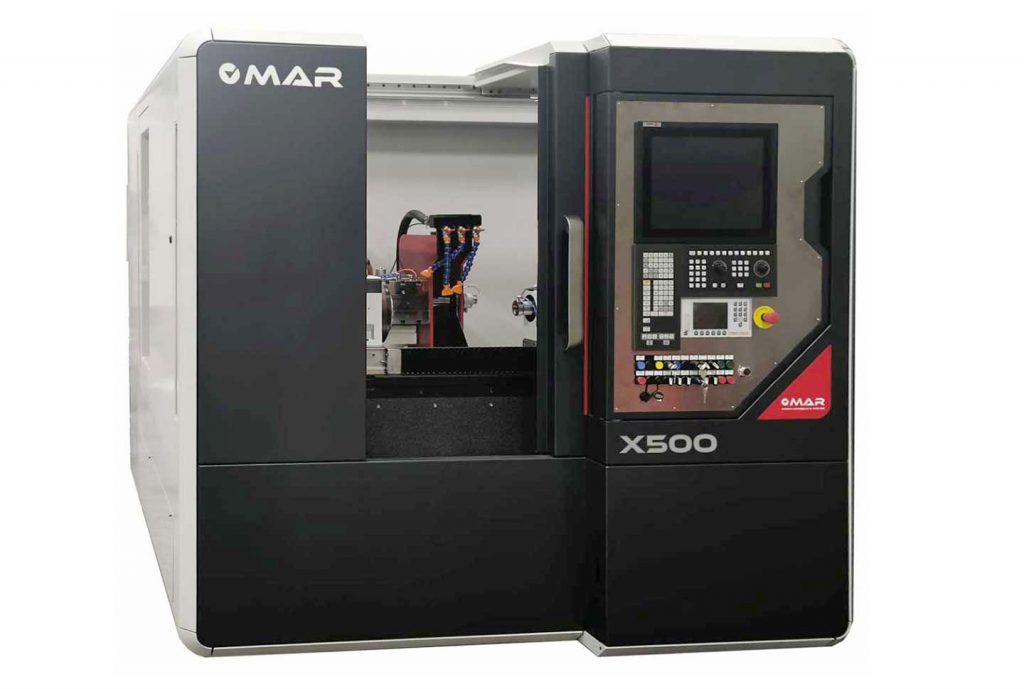

MCR is the smallest grinding machine in the MAR family, designed for high-precision operations. MCR is a compact, modular grinding machine with a sliding table for both internal and external diameters, suitable for working on small pieces with a length of 250 mm and a rotating diameter of up to 250 mm.

MCR is compact grinding machine with mobile panel

All the potentialities of this modular grinding machine in extremely customizable round find expression in a machine with small dimensions

MCR components

Speaking of the parts that specifically compose this machine tool we start from the MCR base – natural granite – made in Italy with the most precise processes that are also used for the creation of counters.

This base has only three levelling points that allow be place the machine on any type of flooring to ensure stability and maximum precision during the working process.

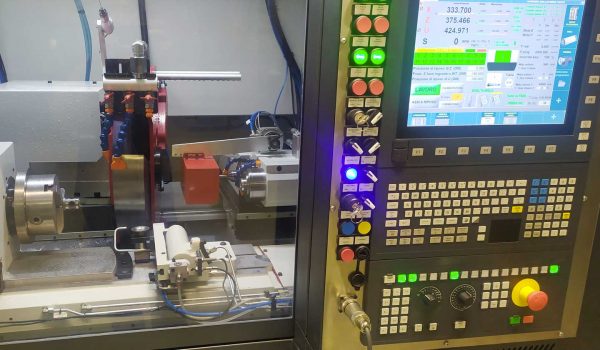

The flat-prismatic sliding of the table is realized directly on the granite surface, with interposition of antifriction material. On this plane of support, the grindstone carriages slide. These carriages boast linear guides with skates to recirculation of rollers and controlled from absolute optical lines pressurized.

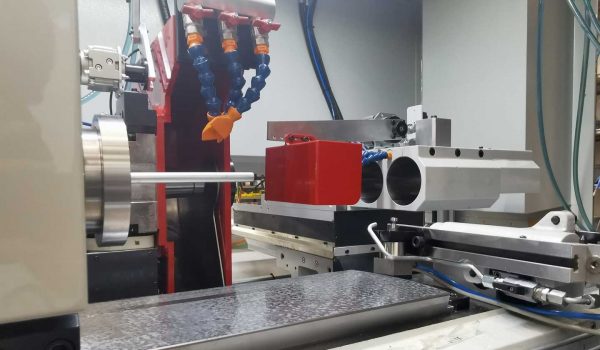

The MCR grinding centre can mount two different carriage wagons. In fact, it is possible to request it exclusively for internal or external diameter machining (with tilting right wheel up to 10 students and dimensions of 508 mm x 60 mm). If necessary, it is also available with two separate units for sequential machining with a single piece grip. During the realization of the MCR modular grinding machine the arrangement of the axes provides a differentiated tuning for each individual tool in order to optimize the processes and speed up the machining, while offering the highest performance. Each linear movement is, in fact, ideally aligned to the machining to be carried out thus reducing the time of movement of the wheel. These optimizations are also possible thanks to advanced control systems that allow the grinding machine mechanics to work at their best.

All the potential of this modular grinding machine finds expression in a machine with small dimensions of 2400 mm x 2000 mm x 2200 mm. It boasts all the necessary parts to create an ideal grinding work station.

Hardware and software of TITAN grinding machine

Like the other machines in the MAR grinding machine family, TITAN is featured with the CN package hardware with the option of choosing between Fagor or Siemens systems, which include drives, motors, and peripherals machine management. The MAR digital technology also includes remote diagnosis tools to be always at the customer’s side in every moment.

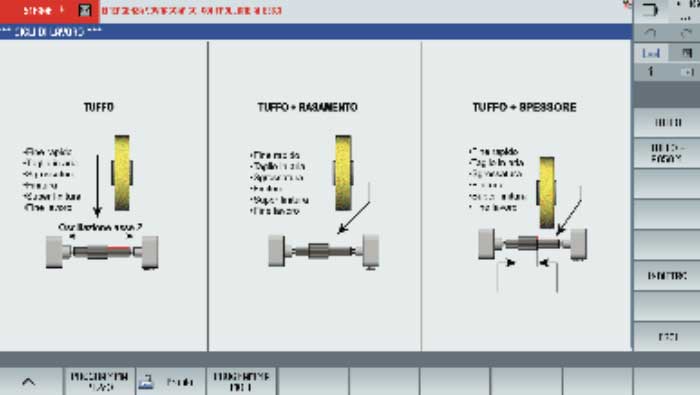

MAR has also fully developed the machine control software, intuitive and straightforward, with a touch screen interface that offers complete control of the machine to operate cycles in total autonomy.

Customization and support

MAR offers the best possible service by collaborating with important companies in the sector to provide all the required customizations to its customers to carry out specific performing work cycles and create a high-quality final product thanks to the processes performed outstanding reliability by MAR grinding machines.

MAR, even after the construction and commissioning of the machine, remains at your side at all times, offering maintenance and support to avoid downtime expensive and easily avoidable. To facilitate any ordinary and non-routine maintenance process, MAR has created TITAN with a design and a layout of the various components aimed not only at optimal operation but also at simple accessibility and easy maintenance in every part of the machine to minimize the time of intervention of its technician’s specialists, who will always know where to act thanks to the field buses and diagnostic systems on each machine.

Finally, MAR also offers a programmed maintenance service to maintain the machine’s workings’ highest quality.